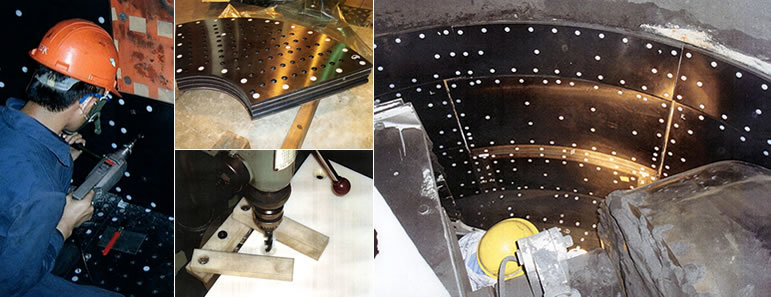

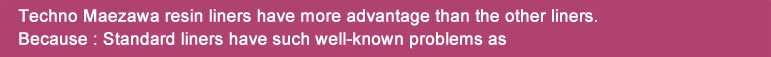

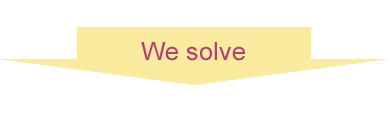

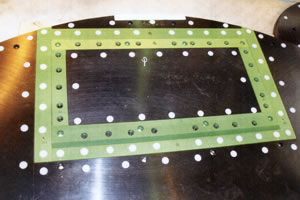

Our gates are made in eight sections using special resin and are angled to shut securely and open without sticking. This system is three or four times stronger than the SS specifications. Each section can be replaced individually. Our system has been designed to fit most type of machines. As the mounting bolts are capped they can be easily removed.

The other sides we have designed more improved 19mm steel plates for gates same as standard for large mixer.